Unveiling the secrets: the art of developing smart connected products.

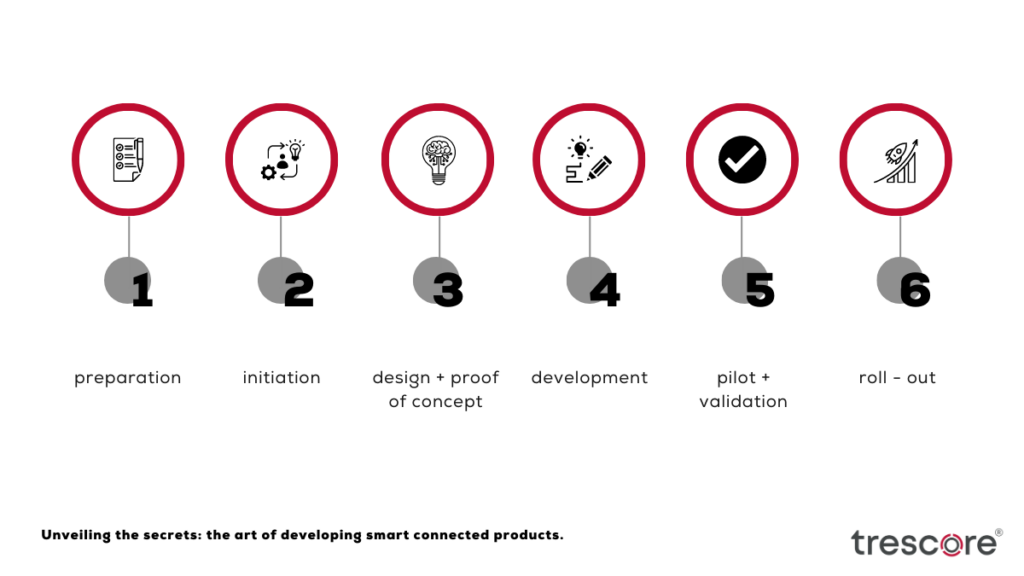

In today’s blog post, we highlight the critical aspects of smart product development and how we typically work with our customers to develop and manufacture innovative IoT solutions from concept to volume production.

In an increasingly connected world, smart products are becoming more and more important. They are not only revolutionizing the everyday lives of consumers: inside, but are also opening up completely new opportunities for companies. The rapid development of the Internet of Things (IoT) has created the basis for these smart products, which improve efficiency, safety and convenience in various areas of life and in companies through their intelligent networking and automation.

Smart products enable unprecedented connectivity and interaction between devices, services and people. By integrating sensors, wireless communications and advanced data processing technologies, devices can communicate with each other, share information and thus act together “intelligently.”

This seamless networking opens up a wide range of possible applications: from smart household appliances and connected vehicles to Industry 4.0 solutions for optimized production in industry.

But what does it take to create innovative and successful solutions? In this article, we will highlight the crucial aspects and show you how we typically work with our customers to develop and manufacture innovative IoT solutions from the idea stage to series production.

1. preparation

Together with our customer, we develop a concrete business case for the planned IoT product and the associated business model. In this first phase, the focus is on validating the product idea and the associated research.

Important questions that need to be answered include: how are competing products doing? What does my target group look like? What requirements does the target group have for the product? What is the potential of the market?

2. initiation

Once the initial framework conditions have been established, the product solution is specified in detail in the form of requirements / functional specifications (electronics development – hardware) and in the form of a product backlog (firmware, cloud backend). It is important to understand the needs and requirements of the IoT product solution precisely.

In so-called requirements engineering workshops, the requirements are discussed, defined and approved together with our customer.

A helpful tool for validating the product solution and the planned business model is the Business Model Canvas. This can provide valuable insights that help to design a product or service that is tailored exactly to the needs of the end customer. With expertise in electronics, software and mechanics, we are able to bring the experts to the table at this early stage and focus on the product benefits.

As a conclusion of the initiation phase, a first concrete schedule is developed and presented with the project partners.

3. design + proof of concept

In this phase, the focus is on the concrete product design, i.e. housing design, material selection, hardware design and the cloud architecture are roughly sketched. It is important to draw the right conclusions about the technologies to be used from the predefined requirements and the business case.

The selection of the right technologies is a decisive factor for the success of smart products. In order to validate technologies and functionalities, a so-called proof of concept is usually used in practice. In a 4-6 week PoC phase, it is determined whether the business case can be realized with the selected technologies. If this is positive, the actual development of the IoT device and the implementation of firmware and software then begins.

Due to the delivery situation of electronic components, it is imperative to coordinate closely with purchasing already in the design phase in order to check delivery times of processors or other components and to make a different selection if necessary.

4. development

The development of the IoT product typically runs in an agile manner and in parallel over several months. Depending on the project scope, a Minimum Viable Product (MVP) can be realized within 3-6 months. Our goal is to minimize the development time to get into field validation with real feedback from “neutral” customers as quickly as possible.

Through our PRINCE2 project management approach we manage to organize the different “trades” while presenting the project status and budget usage in a very transparent way. It is important to us that our customer can assess at any time where we currently stand in the project (schedule, budget, development progress).

At the end of the development phase, initial prototypes are produced, which are then tested in the field during the next phase. Rapid prototyping, i.e. the production of housings from the 3D printer, allows the first product housings to be realized in this early phase.

5. pilot + validation

The goal of this phase is to validate the first prototypes in a field test phase. Feedback is obtained from real, neutral customers and the feedback is precisely documented and analyzed in order to draw conclusions about any user interface adjustments or other desired additional features.

Penetration tests are used to identify weaknesses in the cloud architecture at an early stage and to uncover potential errors. This tests the system for robustness and security.

6. roll-out

Once the IoT device has been validated in the field, initial customer feedback obtained and implemented in development, the approvals start in an accredited test laboratory. This includes EMC tests and safety tests, which are prerequisites for CE marking.

In parallel, series production is prepared in the form of test equipment construction and assembly lines: among other things, test equipment and test systems must be created for this purpose in order to ensure consistently high production quality. Depending on the product and the number of pieces, different assembly techniques (manual, semi-automated, automated) are used.

An important element here is traceability, i.e. the traceability of all materials and components used. In the event of technical problems or software errors, targeted action can be taken very quickly in the field.

In close exchange with our customer, we then create an optimal packaging solution and ship the goods to the end customer, if desired.

Do you need support in the development of networked products from IoT experts? Contact us to discuss the possibilities together and develop individual solutions for your company. Let’s walk the path to a connected future together.

Sind Sie bereit mit uns den

nächsten Schritt zu gehen?

Nehmen Sie jetzt mit uns Kontakt auf und lassen Sie uns gemeinsam das volle Potenzial der Digitalisierung nutzen.

trescore GmbH

Burtenbacher Str. 12

86505 Münsterhausen

0 82 81 - 50 899-40

info@trescore.de